Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

OEM for Auto Stainless Steel Parts

-

≥100/piece

USD 10.00

Established in 2015 and located in Baiyun District, Guangzhou, Guangzhou Jieshi Automotive Accessories Co., Ltd. has been dedicated to the development and production of automotive interior and exterior modification products since its inception. After nearly a decade of steady growth, we have gradually evolved into an influential enterprise in the industry. We boast a mature development team and advanced equipment, enabling us to independently complete the entire process from 3D scanning and 3D modeling to prototyping and mass production, all tailored to customer requirements. Our team members collaborate seamlessly and communicate effectively, ensuring every step is executed efficiently and to the highest quality standards. Additionally, we prioritize team building and development, continuously enhancing the professional expertise and creative capabilities of our members to deliver superior products and services to our clients. Our main business scope includes ABS products and hardware products for automotive interiors and exteriors, with our products primarily exported to countries such as Japan, the United States, and Malaysia.

First and foremost, we have a team of creative and experienced product development engineers who can accurately create high-quality products based on customer requirements.

Secondly, we possess exceptional technical skills and a unique perspective in product design, enabling us to transform 3D scans into competitive styles that meet market demands.

Thirdly, we also value our clients' ideas and, based on their concepts and quality requirements, produce high-quality products that meet their expectations.

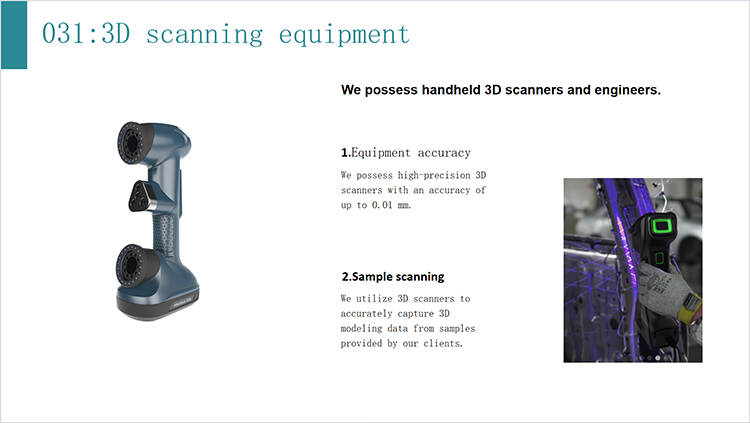

We possess handheld 3D scanners and engineers.

1.Equipment accuracy

We possess high-precision 3D scanners with an accuracy of up to 0.01 mm.

2.Sample scanning

We utilize 3D scanners to accurately capture 3D modeling data from samples provided by our clients.

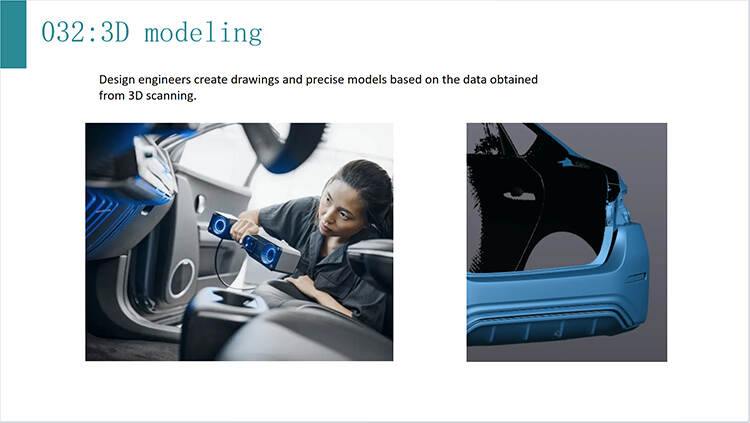

Design engineers create drawings and precise models based on the data obtained from 3D scanning.

1.production equipment

We possess multiple high-precision CNC machines and a team of experienced operating engineers.

2.Mold finished product

We produce high-quality plastic injection or metal molds based on the 3D modeling data provided by our clients.

We have multiple laser cutting machines used for cutting metal products.

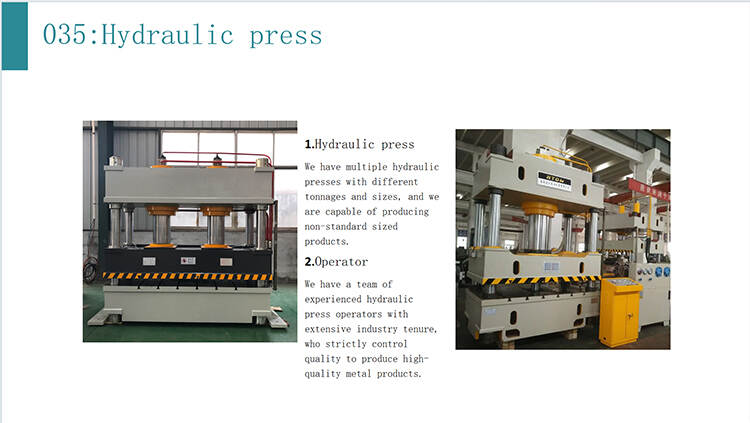

1.Hydraulic press

We have multiple hydraulic presses with different tonnages and sizes, and we are capable of producing non-standard sized products.

2.Operator

We have a team of experienced hydraulic press operators with extensive industry tenure, who strictly control quality to produce high-quality metal products.

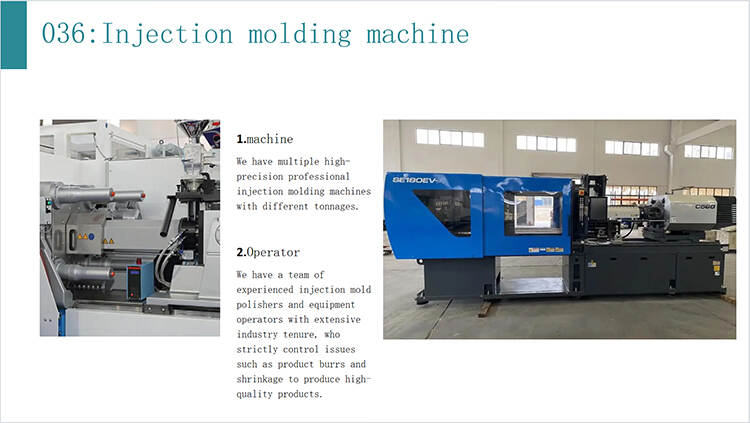

We have multiple high-precision professional injection molding machines with different tonnages.

We have a team of experienced injection mold polishers and equipment operators with extensive industry tenure, who strictly control issues such as product burrs and shrinkage to produce high-quality products.

1.China Trade Shows

We have participated in multiple exhibitions such as the Shanghai Automechanika and the Canton Fair.

2.International trade shows

We have participated in numerous international automotive tuning exhibitions on multiple occasions.

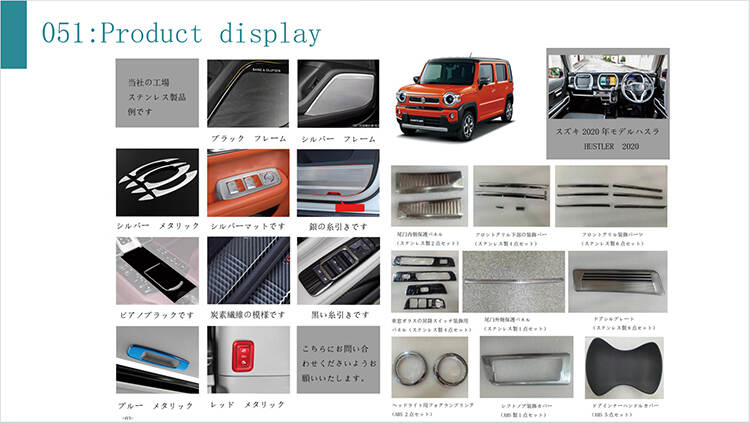

Product display